Product

Menu

Solution

Menu

Technology

Menu

For Scientific Research & Industry Modernisation.

The operating wavelength λB of the fiber Bragg grating (FBG) can be expressed as:

λB = 2neff Λ

Where neff represents the effective refractive index, which is determined by the laser power of processing. While neff is precisely controlled and stable, the grating period Λ determines the operating wavelength of the FBG. Therefore, the consistency of the FBG period determines the quality of the fabricated FBGs.

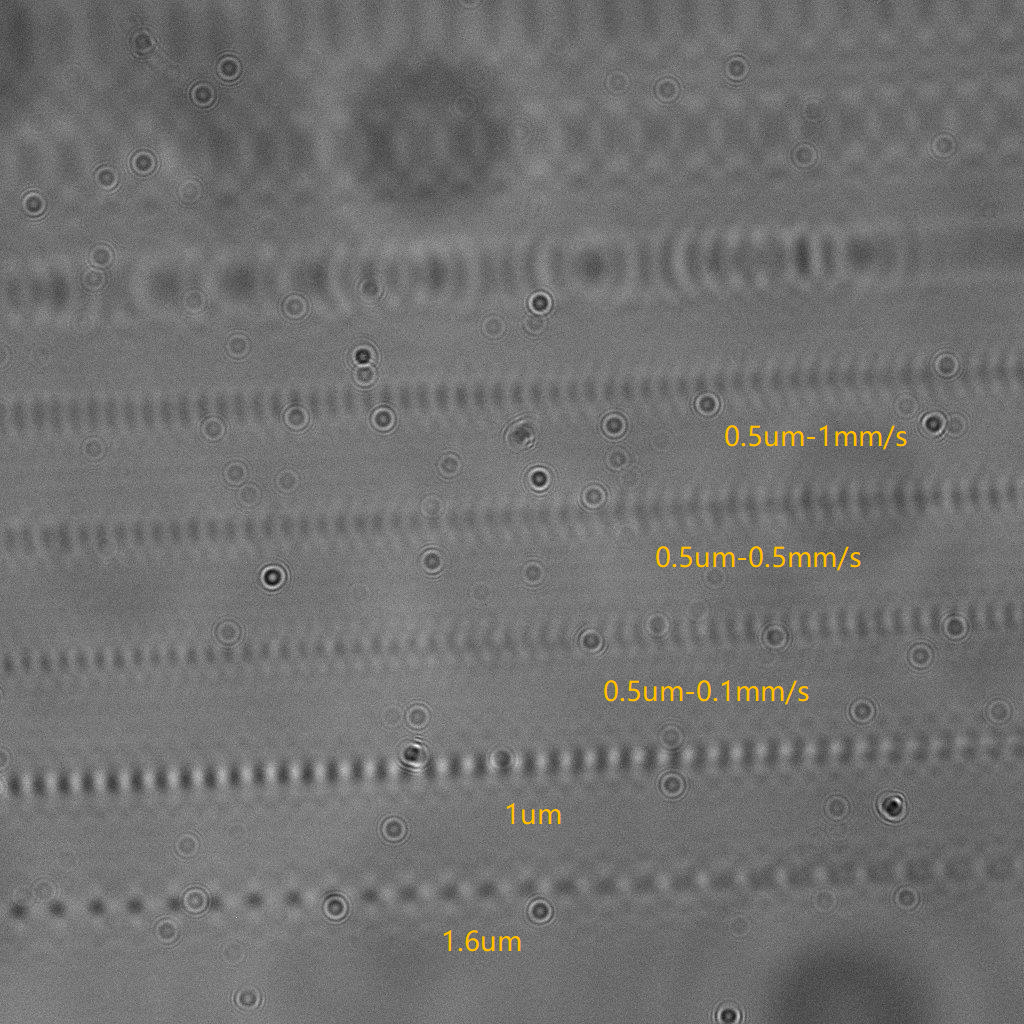

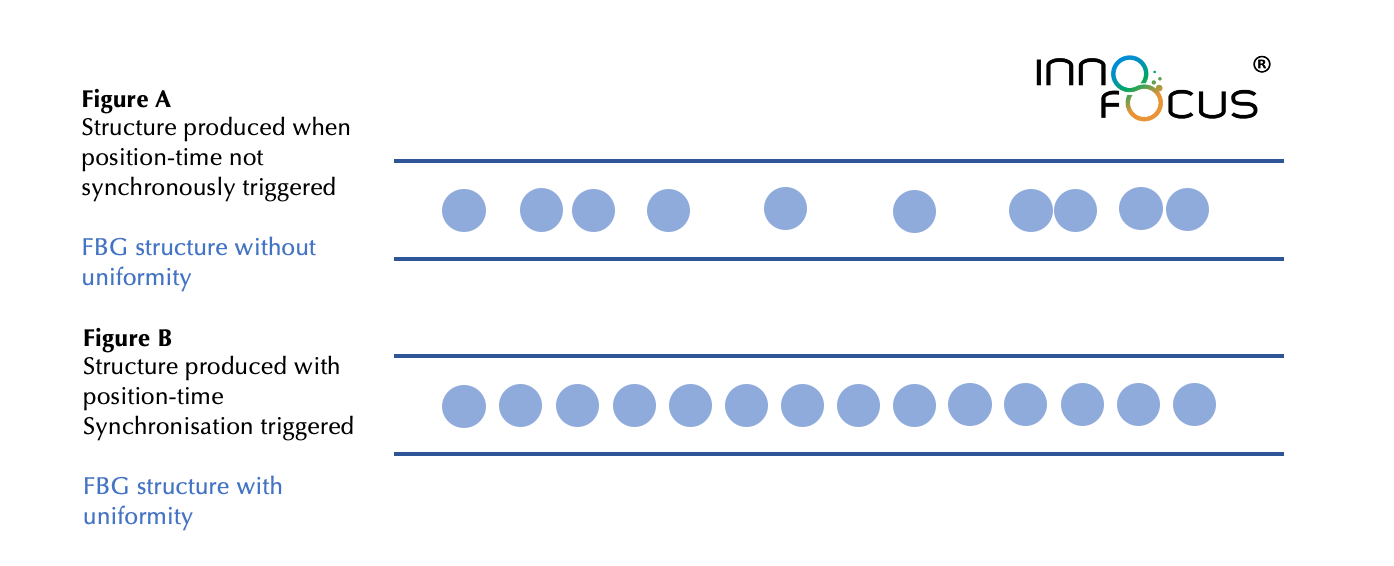

As shown in Figure 1A, the spacings between each point in the fiber core are inconsistent, resulting in an inconsistent grating period during FBG fabrication. The quality and performance of the fabricated FBG will hence be significantly affected. There are two major effects:

These effects will ultimately lead to a significant reduction in device performance and product yield. Therefore, effective control of accurate and uniform spacings between each points to ensure a consistent period of the fabricated FBG is the decisive factor in improving the performance of FBG devices.

Fig 1. Schematic demostration of the position-time synchronized trigger during the fabrication of FBG. Blue lines represent the edges of fiber core, and dots represent fabricated points.

When fabricating FBG, the conventional method to fabricate periodic grating structures is to maintain consistent laser exposure intervals assuming the scanning stage is moving at a constant speed. In this way, the spacing between each point can be maintained constant. It can be expressed as:

Λ = v∆t

where v is the speed at which the scanning stage is moving, and Δt is the time interval. Such a method can achieve relatively uniform exposure to a certain extent. However, in an actual fabrication process, the scanning stage constantly accelerates and decelerates, and achieving a constant speed of motion is hardly possible. The speed at different times can be expressed as v + Δv, where Δv depends on the accuracy of speed control, the mass of the scanning stage, and its acceleration. Especially when the scanning stage moves at high speed (generally, the scanning stage is controlled to move at high speed to save fabrication time), the stability of its velocity is difficult to control accurately. This introduces ΔΛ=ΔvΔt, which leads to the variation in the period and degrades the quality, as shown in Figure 1, A.

Effective control of accurate and uniform spacings between each points to ensure a consistent period of the fabricated FBG is the decisive factor in improving the performance of FBG devices. To address, Innofocus has developed PTST function module which enables accurate trigger of laser exposure at the desired positions by precisely synchronizing the position detection and laser trigger.

To solve this challenge, based on the strong R&D capabilities and the collaborative research on hardware, software, and algorithms, Innofocus have developed the PTST (Position-Time Synchronized Trigger) module. The PTST technology has been integrated into Innofocus’ world-leading nanoLAB 3D intelligent laser nanofabrication system. This function module enables highly intelligent and precise control of the position and time of laser exposure. Unlike conventional control of constant exposure intervals, PTST can enable accurate trigger of laser exposure at the desired positions by precisely synchronizing the position detection and laser trigger. This avoids the uncertainty of the spacings between each exposure and ensures consistent spacings between each point in the FBG. As shown in Figure 1B, the uniform structure in the fiber core with a consistent period can effectively improve the fabrication quality and yield.

Femtosecond laser processing with the NanoPrint 3D Intelligent Nano-fabrication system allows direct writing of micro-, sub-micron and even nano-scale 3D micro and nano structures in transparent media, with the advantages of maskless, flexible structure, simple design and fast processing speed. By combining with different optical materials, it can achieve a wide range of applications in the field of all-optical communication, especially in the fabrication of diffractive optics, integrated optics, on-chip optics, silicon photonics, nano-optics, and quantum optics, which stand out among the many micro and nano fabrication technologies and become increasingly important in enabling technology.

Three-dimensional micro-nano structures can be designed to enhance the interaction between the local optical field and matter, thus giving rise to a variety of linear and non-linear optical phenomena and shortening the scale of action, thus effectively achieving miniaturization, integration and low energy consumption of devices. For example, Nanoprint 3D Intelligent Laser Nano-Fabrication system can realize various miniature diffractive optical elements including micro-lens, integrated grating, and waveband sheet, which can play a great role in imaging, wavelength selection and dispersion compensation.

In addition, the NanoPrint system’s unique high-power femtosecond laser enables interaction with different materials such as glass, silicon, sulfur-based glass, and lithium niobate crystals. These materials can effectively introduce nonlinear optical interactions for wavelength conversion, optical switching, nonlinear tuning, etc. Nonlinear interactions in nanoscale waveguides can be exploited to generate effective sources of entangled photons for quantum optics. Femtosecond lasers can introduce ultra-high refractive index changes in optical fibers, bulk glass, and two-dimensional materials to form high-quality optical waveguides, ultra-thin devices, and complex three-dimensional integrated optical systems such as optical connectors and on-chip integration, which are essential enabling components for ultrafast, ultra-high-capacity, and quantum communications

In today’s society where everything is smart, sensors are playing an increasingly important role in our daily lives and in the Internet of Things. Sensors monitor our health (e.g. heartbeat), air quality, home security, and are widely used in the Industrial Internet of Things (IIoT) to monitor production processes. Our lives are surrounded by smartphones, wearables, and other smart devices, all of which are inseparable from sensors.

Widely used sensors in daily life include thermometers, pressure sensors, light sensors, accelerometers, gyroscopes, motion sensors, gas sensors and so on. Their design and manufacturing often rely on traditional electromechanical processing, which has a single function, large size and high energy consumption, and is not suitable for the new sensor miniaturization, integration, integration, high precision and low energy requirements. Therefore, how to innovate fabrication methods and improve the fabrication process has become a difficult problem in the field of sensing.

The NanoPrint 3D Intelligent Laser Nano-fabrication System can write flexible design and versatile 3D micro-nano structures in a variety of materials including polymers, 2D materials, metals, semiconductors, crystals, optical fibers, and other materials to form sensing mechanisms. Its writing method is flexible and simple to fabricate, and no vacuum or mask is required. More importantly, the written structure is small and highly integrated, and can form an immersion sensing with the substrate or environment. It is also possible to introduce in-situ high-precision sensors directly at the sites that need to be measured in sensing, without damaging the original environment and overall appearance.

In particular, graphene micro and nano sensors realized with NanoPrint system have been playing an important role in artificial skin, intelligent robots, health care, early diagnosis of diseases, wearable devices, etc. in recent years. In addition, FBG fabricated by the unique patented technology with NanoPrint system has the characteristics of easy operation, fast writing speed, stable process, flexible formation of a variety of special grating, and high raster rate. It solves the problems of expensiveness, complex process and single grating structure with the traditional fiber grating fabrication equipment. The formed FBG has large change in refractive index, high temperature resistance, high performance index and good stability, has replaced the traditional fiber grating and plays an irreplaceable role in the high temperature and high pressure environment.