Product

Menu

Solution

Menu

Technology

Menu

For Scientific Research & Industry Modernisation.

Fiber Bragg gratings (FBGs) manufactured by femtosecond laser technology possess significant advantages over conventional FBGs fabricated by ultraviolet lasers. This is due to the large refractive index difference introduced by a femtosecond laser, which can be up to 10-3 (Δn ∽ 10-3). Femtosecond laser manufactured FBGs offer two major advantages:

Therefore, the future trend in the field of FBG manufacturing is to achieve high-quality FBGs manufactured using femtosecond lasers. During the manufacturing process of FBGs with femtosecond lasers, the refractive index difference introduced by the laser directly determines the quality of the produced FBGs. When the refractive index difference produced by the laser processing is well controlled, each point’s size and refractive index distribution can be kept consistent for achieving high-performance FBGs. Each point’s refractive index difference is mainly determined by the interaction of light and material, which can be expressed as:

Δn = f(Pt)

where Δn represents the refractive index difference introduced by a laser, f is an arbitrary function determined by the material being processed, P is the laser power, and t denotes the exposure time. Thus, the refractive index difference is determined by both the material’s response and the laser’s parameters. The f varies depending on the materials.

Therefore, ensuring the consistency of the laser power and exposure time is the determining factor for achieving a consistent refractive index difference (Δn).

High power stability and precise power control are essential to guarantee the high-quality manufacturing of fibre Bragg grating (FBG). PowerFlex is a fully automated laser power control technology that enables precise control of laser power at a step of 1µW.

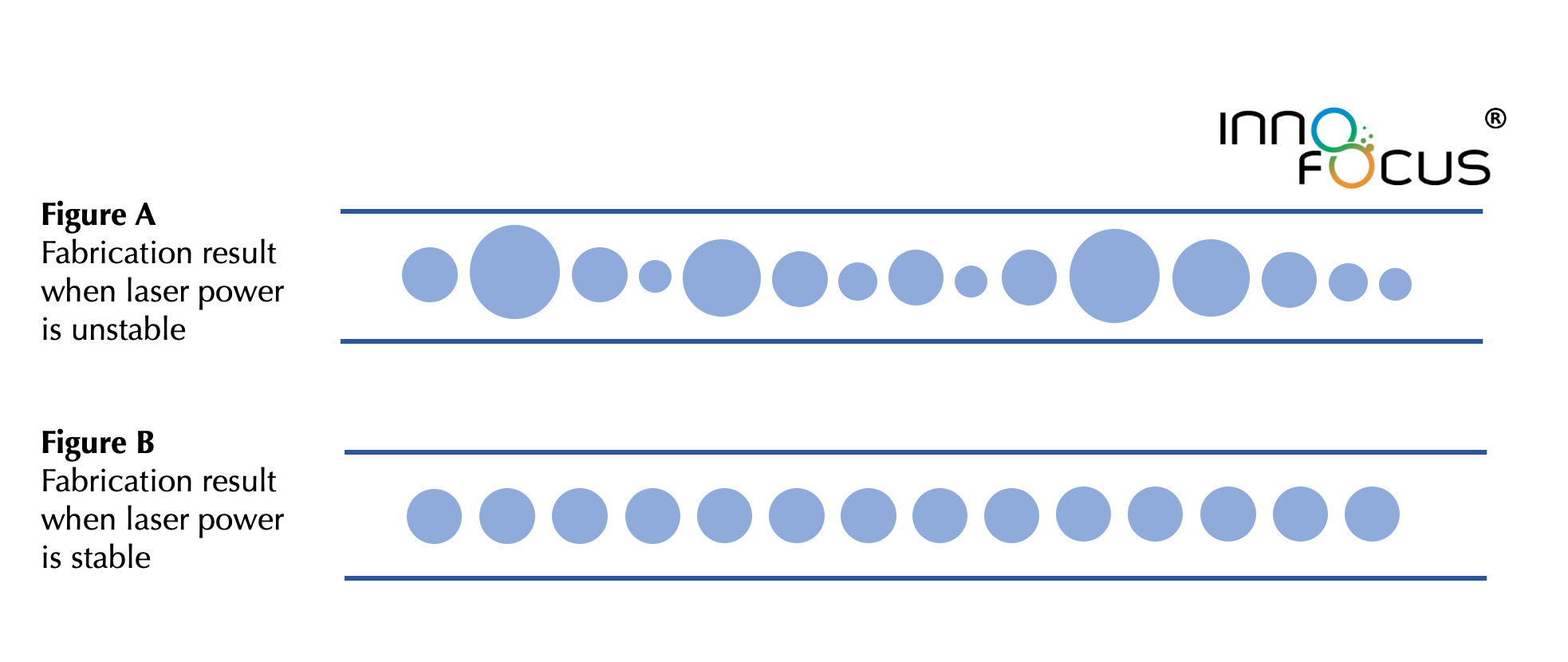

Fig 1. Comparison of FBG grid points for stable and unstable laser power processing. The blue line represents the fiber core and the dot represents the grid point of laser processing.

During the manufacturing process, the controlled exposure time can be very precise, at the order of 0.001ms, so the exposure time can be maintained very consistently. In addition, controlling laser power stability is essential to ensure consistent refractive index differences. In this regard, Innofocus uses a highly stable femtosecond laser with a real-time pulse power monitoring system. The monitoring system guarantees the stability of laser pulses during long-time continuous operation (>100 hours), and the fluctuation of a single pulse can be controlled within <1%. It enables continuous stable FBG manufacturing and ensures the consistency of the refractive index of each point. It lays a solid foundation for realizing high-performance FBG manufacturing. A schematic of the comparison is shown in Figure 1. Suppose the laser power is not stable. In that case, the distribution of refractive index within the fiber during manufacturing will be uneven, as shown in the case of Figure A, causing an overall lower quality of FBG. Innofocus’s high-stability laser can output stable power values for a long time to ensure a uniform refractive index distribution.

In addition to high power stability, precise power control to adjust the points’ size, and refractive index difference Δn are extremely important in optimizing FBG parameters and manufacturing different types of FBGs. To meet this requirement, Innofocus has developed the PowerFlex, a precise power control module. PowerFlex is a fully automated laser power control technology that enables precise control of laser power at a step of 1µW.

Our intelligent femtosecond laser power control technology can also meet the needs of introducing different refractive index distributions. As shown in Figure 2, the points in an FBG manufactured by a high laser power are larger in size with a higher refractive index change (Figure A), whereas points manufactured at a low power are smaller in size (Figure B). By changing the system’s parameters, various flexible needs can be met. The fully automated power system effectively avoids the variation in quality caused by laser power fluctuation. It allows for long-time, large-scale, repeated FBG manufacturing, resulting in high-quality mass production of FBG.

Fig 2. Schematic figure of FBG points processed with different laser processing powers.

Femtosecond laser processing with the NanoPrint 3D Intelligent Nano-fabrication system allows direct writing of micro-, sub-micron and even nano-scale 3D micro and nano structures in transparent media, with the advantages of maskless, flexible structure, simple design and fast processing speed. By combining with different optical materials, it can achieve a wide range of applications in the field of all-optical communication, especially in the fabrication of diffractive optics, integrated optics, on-chip optics, silicon photonics, nano-optics, and quantum optics, which stand out among the many micro and nano fabrication technologies and become increasingly important in enabling technology.

Three-dimensional micro-nano structures can be designed to enhance the interaction between the local optical field and matter, thus giving rise to a variety of linear and non-linear optical phenomena and shortening the scale of action, thus effectively achieving miniaturization, integration and low energy consumption of devices. For example, Nanoprint 3D Intelligent Laser Nano-Fabrication system can realize various miniature diffractive optical elements including micro-lens, integrated grating, and waveband sheet, which can play a great role in imaging, wavelength selection and dispersion compensation.

In addition, the NanoPrint system’s unique high-power femtosecond laser enables interaction with different materials such as glass, silicon, sulfur-based glass, and lithium niobate crystals. These materials can effectively introduce nonlinear optical interactions for wavelength conversion, optical switching, nonlinear tuning, etc. Nonlinear interactions in nanoscale waveguides can be exploited to generate effective sources of entangled photons for quantum optics. Femtosecond lasers can introduce ultra-high refractive index changes in optical fibers, bulk glass, and two-dimensional materials to form high-quality optical waveguides, ultra-thin devices, and complex three-dimensional integrated optical systems such as optical connectors and on-chip integration, which are essential enabling components for ultrafast, ultra-high-capacity, and quantum communications

In today’s society where everything is smart, sensors are playing an increasingly important role in our daily lives and in the Internet of Things. Sensors monitor our health (e.g. heartbeat), air quality, home security, and are widely used in the Industrial Internet of Things (IIoT) to monitor production processes. Our lives are surrounded by smartphones, wearables, and other smart devices, all of which are inseparable from sensors.

Widely used sensors in daily life include thermometers, pressure sensors, light sensors, accelerometers, gyroscopes, motion sensors, gas sensors and so on. Their design and manufacturing often rely on traditional electromechanical processing, which has a single function, large size and high energy consumption, and is not suitable for the new sensor miniaturization, integration, integration, high precision and low energy requirements. Therefore, how to innovate fabrication methods and improve the fabrication process has become a difficult problem in the field of sensing.

The NanoPrint 3D Intelligent Laser Nano-fabrication System can write flexible design and versatile 3D micro-nano structures in a variety of materials including polymers, 2D materials, metals, semiconductors, crystals, optical fibers, and other materials to form sensing mechanisms. Its writing method is flexible and simple to fabricate, and no vacuum or mask is required. More importantly, the written structure is small and highly integrated, and can form an immersion sensing with the substrate or environment. It is also possible to introduce in-situ high-precision sensors directly at the sites that need to be measured in sensing, without damaging the original environment and overall appearance.

In particular, graphene micro and nano sensors realized with NanoPrint system have been playing an important role in artificial skin, intelligent robots, health care, early diagnosis of diseases, wearable devices, etc. in recent years. In addition, FBG fabricated by the unique patented technology with NanoPrint system has the characteristics of easy operation, fast writing speed, stable process, flexible formation of a variety of special grating, and high raster rate. It solves the problems of expensiveness, complex process and single grating structure with the traditional fiber grating fabrication equipment. The formed FBG has large change in refractive index, high temperature resistance, high performance index and good stability, has replaced the traditional fiber grating and plays an irreplaceable role in the high temperature and high pressure environment.