Product

Menu

Solution

Menu

Technology

Menu

INNOFOCUS

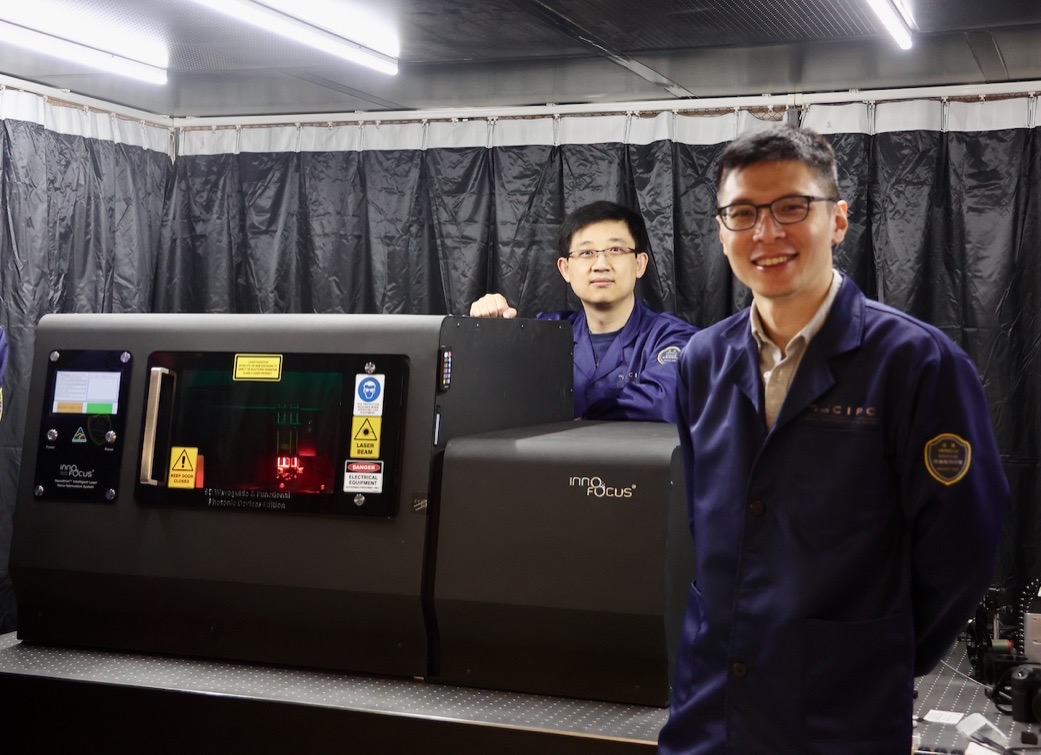

Demonstrating our commitment to continuous innovation and open collaborations with our clients, industry partners and research institutes across disciplines, Innofocus has built the World’s First Nano Manufacturing Plant (NMP) in Heidelberg, Melbourne, with 1000 square meters of office, open labs and customer innovation workshop.

Innofocus endeavours to accelerate the worldwide transformation into the nano-manufacturing era and our NMP will facilitate more novel products and solutions in the forms of next-generation equipment, devices and materials. This state-of-art facility will showcase our world-leading technology to the public and help them understand the innovations that, Frank, our CEO added,

INNOFOCUS

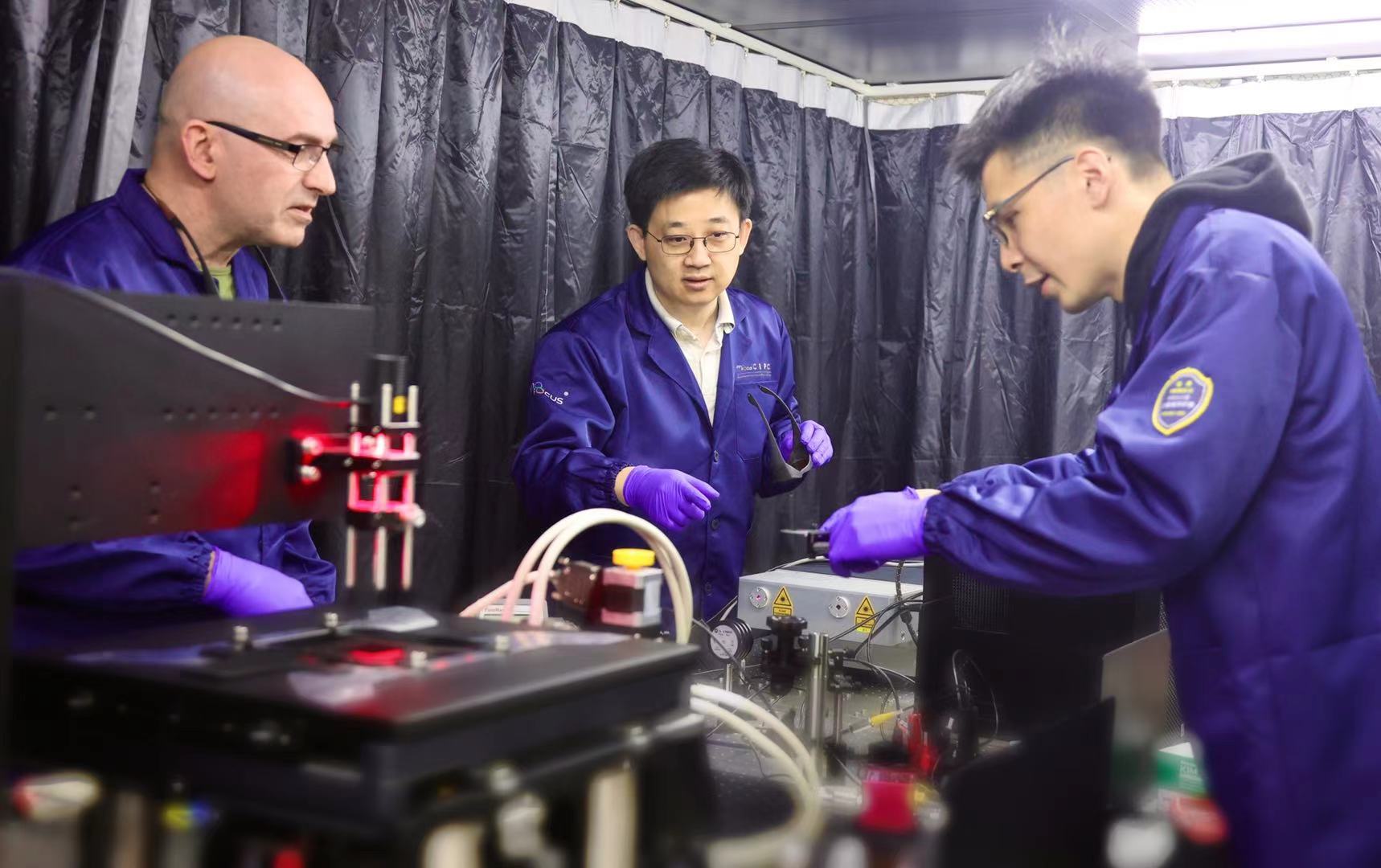

The Innofocus team has been long committed to open collaborations with our customers, industry partners and research institutions, enabling the development and perfection of their work. To foster more connections and collaboration, and to discover more industry needs and challenges, we have established Customer Innovation & Practice Centre (CIPC), invested in the laboratory space in our Nano Manufacturing Plant (NMP), working towards a multitude of innovation through nanomanufacturing.

CIPC will serve as a practical platform to connect and unite resources across academia, government, and industry leaders, opening up new opportunities for more research avenues and industrial applications.

Since 2019, CIPC has been developing long-term relationship with our customers, industry partners and research collaborators, dedicating to prototyping and development services with our world-leading nano-manufacturing capabilities.

We welcome companies and research institutions from various disciplines, such as optical communication & sensing, microfluidic devices, optical imaging, biomedical research, food and agriculture, pharmaceuticals and etc.

INNOFOCUS

INNOFOCUS

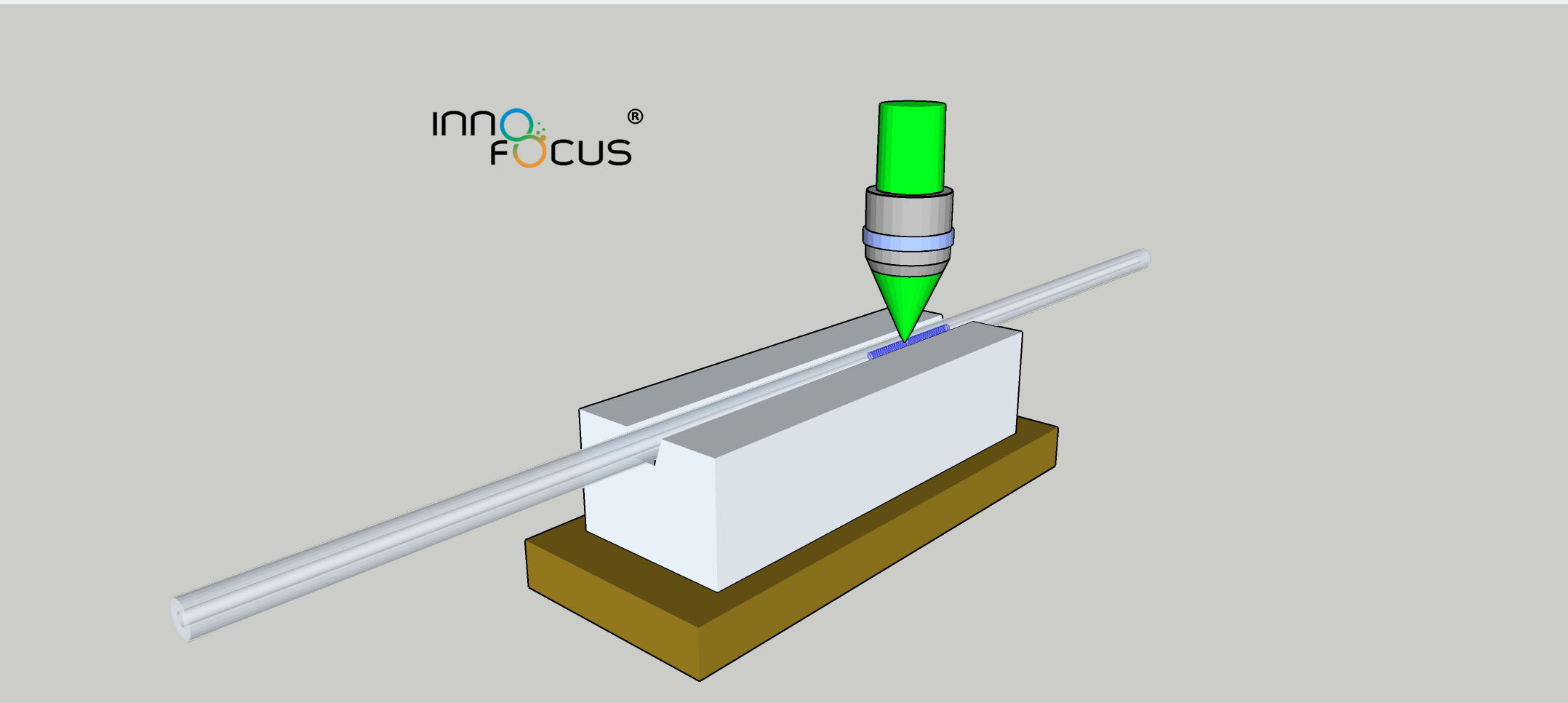

Laser fabricating of polymer materials can be applied in:

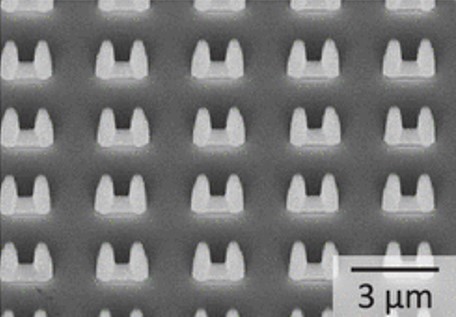

Complex 3D structure fabrication

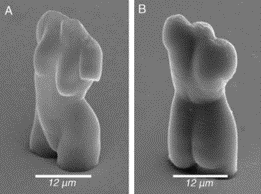

Biological applications

Biological cells

Surface relief type optical element

3D photonic crystal

Optical waveguide coupler

Optical biomimetics

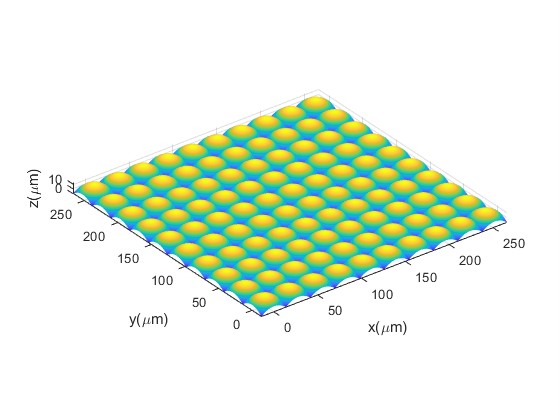

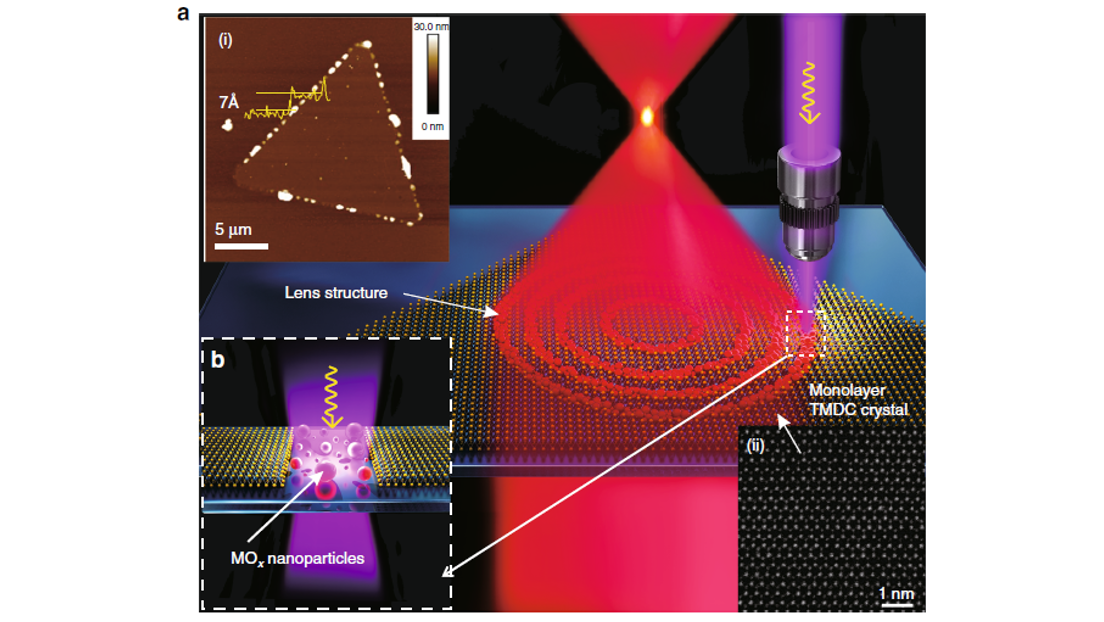

Ultrathin flat optics allow control of light at the subwavelength scale that is unmatched by traditional refractive optics. To approach the atomically thin limit, the use of 2D materials is an attractive possibility due to their high refractive indices. However, achievement of diffraction-limited focusing and imaging is challenged by their thickness-limited spatial resolution and focusing efficiency. Here we report a universal method to transform 2D monolayers into ultrathin flat lenses. Femtosecond laser direct writing was applied to generate local scattering media inside a monolayer, which overcomes the longstanding challenge of obtaining sufficient phase or amplitude modulation in atomically thin 2D materials. We achieved highly efficient 3D focusing with subwavelength resolution and diffraction limited imaging. The high focusing performance even allows diffraction-limited imaging at different focal positions with varying magnifications. Our work paves the way for downscaling of optical devices using 2D materials and reports an unprecedented approach for fabricating ultrathin imaging devices.

This paper was titled “Diffraction-limited imaging with monolayer 2D material-based ultrathin flat lenses” and published on Light: Science & Applications. The first author is Dr. Han Lin.

Read more:

The development of ultrathin flat lenses has revolutionized the lens technologies and holds great promise for miniaturizing the conventional lens system in integrated photonic applications. In certain applications, the lenses are required to operate in harsh and/or extreme environments, for example aerospace, chemical, and biological environments. Under such circumstances, it is critical that the ultrathin flat lenses can be resilient and preserve their outstanding performance. However, the majority of the demonstrated ultrathin flat lenses are based on metal or semiconductor materials that have poor chemical, thermal, and UV stability, which limit their applications. Herein, we experimentally demonstrate a graphene ultrathin flat lens that can be applied in harsh environments for different applications, including a low Earth orbit space environment, strong corrosive chemical environments (pH = 0 and pH = 14), and biochemical environment. The graphene lenses have extraordinary environmental stability and can maintain a high level of structural integrity and outstanding focusing performance under different test conditions. Thus, it opens tremendous practical application opportunities for ultrathin flat lenses.

This paper was titled “Resilient Graphene Ultrathin Flat Lens in Aerospace, Chemical, and Biological Harsh Environments” and published on ACS Appl. Mater. Interfaces. The first author is Dr. Guiyuan Cao.

Read more:

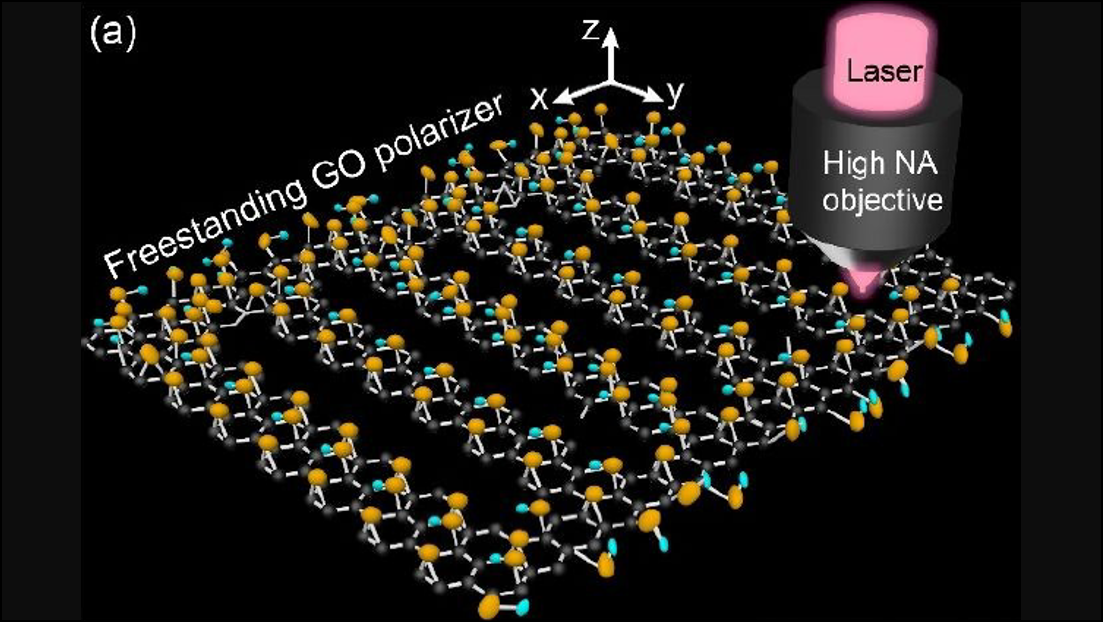

Mid-infrared (MIR) represents crucial spectral region for applications in spectroscopy, sensing, imaging, security and industry screening, owing to the strong characteristic vibrational transitions of many important molecules. However, the current MIR compatible materials are fragile, hazardous, and costly, which hampers the performance of MIR devices. Here, we developed a versatile transmittance-based Kramers-Kronig method and obtained the optical properties of graphene oxide in the MIR region, unveiling its application potentials as a novel MIR compatible material. As an example, we demonstrated free-standing graphene oxide MIR polarizers with large extinction ratio (~ 20 dB) and controllable working wavelength up to 25 μm, by using the low-cost and flexible direct laser writing technique. Our transmittance-based KK method offers a versatile approach to obtain the optical properties of novel atomic-scale low-dimensional materials in the less developed MIR region and opens up opportunities in high performing functional MIR devices.

This paper was titled “Free-standing graphene oxide mid-infrared polarizers” and published on Nanoscale. The first author is Xiaorui Zheng.

Read more:

https://pubs.rsc.org/en/content/articlelanding/2020/nr/d0nr01619e/unauth#!divAbstract