Product

Menu

Solution

Menu

Technology

Menu

For Scientific Research & Industry Modernisation.

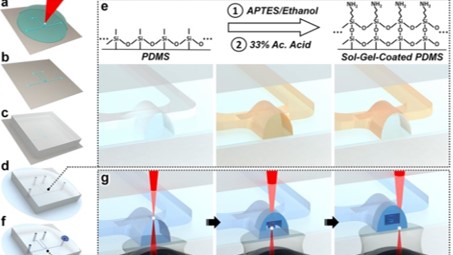

Microfluidic devices have become a platform for high-throughput sorting, analysis, and assembly in the pharmaceutical industry, nanomaterials science, and other fields. Conventional microfluidic devices are fabricated by photolithography, which makes it difficult to fabricate complex three-dimensional structures. Combined with chemical etching, DLW has become a widely used approach for 3D microfluidic device fabrication.

Fig. Engineers at the University of Maryland (UMD) have created the first 3D-printed fluid circuit element so tiny that 10 could rest on the width of a human hair. The diode ensures fluids move in only a single direction — a critical feature for products like implantable devices that release therapies directly into the body. (Source from: https://www.eurekalert.org/multimedia/765951)

In recent years, femtosecond pulsed lasers have been widely used in microfluidic devices, microsensors, biomedical and other micro and nano manufacturing fields. Especially in the biomedical field, the laser can realize complex and fine micro and nano structure processing, which can best meet the requirements of some special applications of biomedical products.

Compared with traditional fabrication methods, femtosecond pulsed laser micro-fabrication has the advantages of “cold” processing, low energy consumption, low damage, high precision, and strict positioning in 3D space, which has a good prospect in biological device fabrication. Laser micromachining technology gives new structures and functions to biological materials and can be used for cell culture to achieve permanent repair of damaged tissues or organs, which has become the development direction of contemporary biomedicine.

Although laser micro-fabrication technology can fabricate a new generation of implantable medical devices with extremely fine structures, making the next generation of implantable medical devices commercially viable, the development of laser micro-fabrication technology in the biomedical field is still immature, with low production efficiency and working stability to be improved.

For laser micro-fabrication, there is no complete set of theories to explain the physical nature of laser-material interaction under the extreme conditions of ultra-fast, ultra-short and ultra-intense, and the impact of laser micro-fabrication on the material structure and its physical and chemical properties cannot be well evaluated. The next step of work still needs a lot of basic and regular research, and at the same time, we need to develop simulation and analysis software to simulate the micro-fabrication process and optimize the parameters of the laser micro-fabrication process according to the characteristics of laser micro-fabrication and the properties of the fabricated material.

NanoPrint 3D Intelligent Laser Nano-Fabrication system can be widely used in biology for surface micro-fabrication of biomaterials, preparation of medical MEMS components, processing of vascular scaffold structures, rapid prototyping of biological scaffolds and cell feeding scaffolds.